Traditional welding training 1940

Traditional welding training 2000

Introduction:

Welding is a critical skill in various industries, and the demand for skilled welders continues to grow. Aspiring welders and students in vocational programs often face challenges when it comes to acquiring hands-on experience due to safety concerns and the cost of materials. However, the emergence of advanced welding simulators has revolutionized the way students learn and practice welding techniques. In this article, we will explore the benefits of using a state-of-the-art welding simulator for training, highlighting its impact on skill development, safety, and cost-effectiveness.

Skill Development and Mastery:

Welding simulators offer a platform for students to develop and refine their welding skills. Through simulated practice, students can focus on specific techniques, welding positions, or welding processes, honing their abilities through repetition. The simulator provides immediate feedback on the quality of the weld, enabling students to identify flaws and make necessary adjustments in real-time. This iterative process accelerates skill development and helps students achieve mastery in welding techniques.

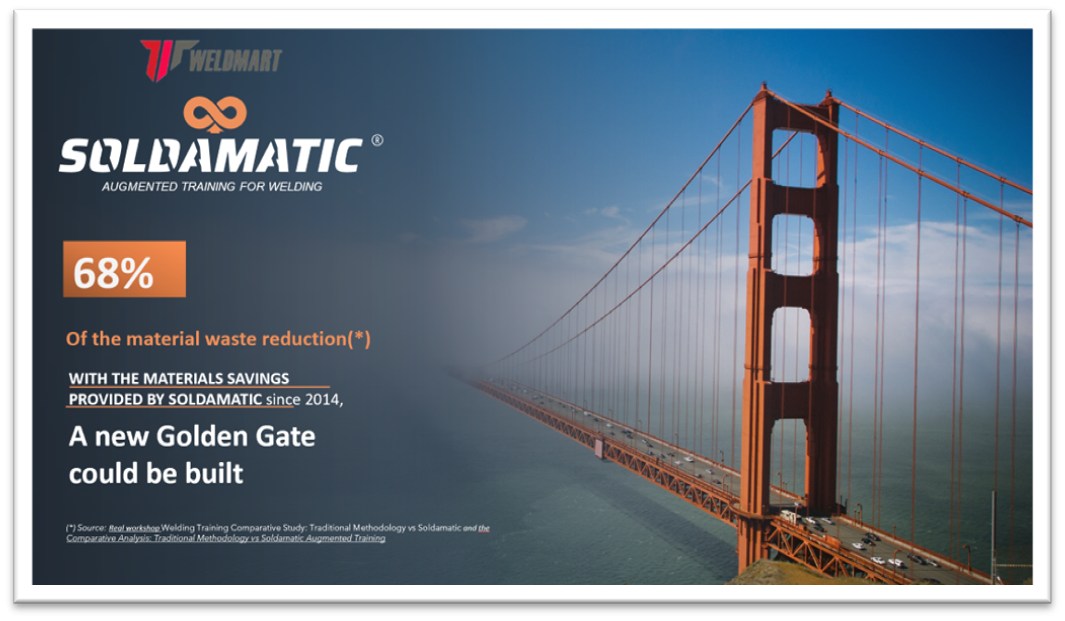

Cost-Effectiveness:

Acquiring physical welding equipment, materials, and consumables can be a significant financial burden for students. A welding simulator offers a cost-effective alternative by eliminating the need for expensive resources. Students can practice as much as they desire without worrying about material waste or the depletion of consumables. Moreover, the simulator reduces maintenance costs associated with real equipment, making it an economical choice for educational institutions.

Material Savings

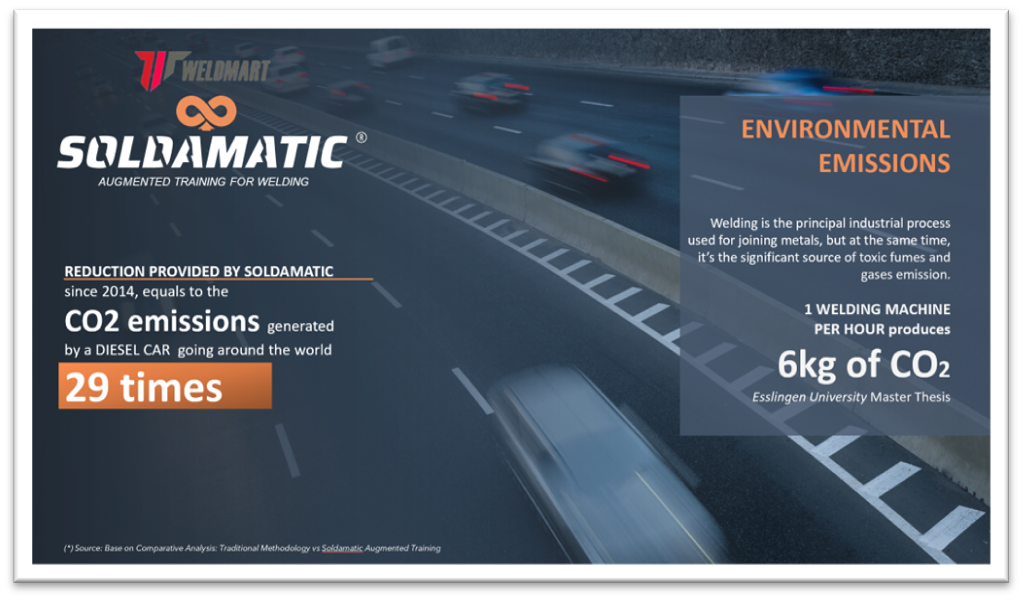

Environmental Impact

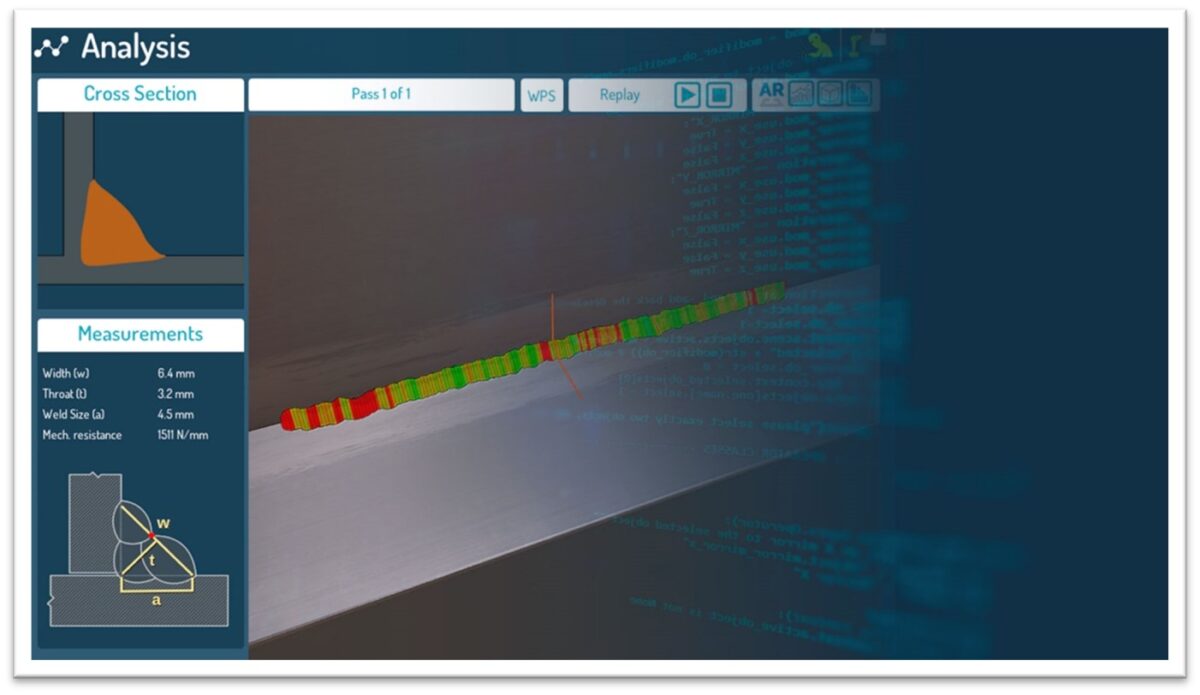

Progress Monitoring and Analysis:

Advanced welding simulators include monitoring and analysis features that facilitate performance evaluation. Instructors can track students’ progress, analyse their welding techniques, and provide targeted feedback for improvement. The recorded data enables instructors to identify areas where students need additional support, ensuring a personalized learning experience. This data-driven approach enhances the effectiveness of training and maximizes student outcomes.

Welding Analysis with WPS

Conclusion:

A cutting-edge welding simulator for training is an invaluable tool that enhances the learning experience for aspiring welders and students in vocational programs. By offering a safe and immersive environment, the simulator allows for skill development, provides cost-effective training, and prepares students for real-world welding applications. Educational institutions and students alike can benefit from the advantages of a welding simulator, empowering the next generation of skilled welders with the proficiency and confidence needed for success in the welding industry.Top of Form Bottom of Form

Augmented Reality Welding Simulator

Augmented Lab