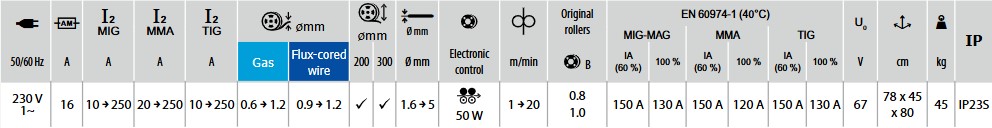

GALAXY 250M is a multi-process, single-phase inverter welding machine. With a MIG/MAG pulse function, it delivers very precise control of the welding energy, reducing deformation of the workpiece. Pulse synergy increases welding speeds and reduces spatter, while also improving the aesthetics of the weld bead. Excellent for welding thin aluminium and stainless steel, the GALAXY 250M is a modern workshop solution for smooth, touch-up-free welds.

MULTI-PROCESS

A power source for all manual welding applications

- MIG/MAG pulse:

– Steel wire: Ø 0.6 to 1.0 mm

– Stainless steel wire: Ø 0.8 to 1.0 mm

– Aluminium wire: Ø 0.8 to 1.2 mm

– Flux-cored wire (inverted polarity): Ø 0.9 to 1.2 mm

- MMA DC / Pulse: basic and rutile electrodes

- TIG DC Lift / Pulse

PREMIUM MIG/MAG WELDING

- 4 welding modes:

– Standard: ideal for fast, simple welding applications

– Pulse: reduces spatter and touch-ups in all welding positions

– ModulArc: ideal for assembling aluminium alloys that require aesthetic appeal

– Manual: suitable for experienced welders and DMOS welding

- Digital arc control with instant ignition and no cratering at the end of the bead

- Arc pulse delivers up to 30% higher welding speeds

- 4-roller motorized wire feeder with digital encoder for precise wire feed

INTELLIGENT

- +40 synergies on various materials: Steel, AlMg, AlSi, CrNi, CuSi.

- New intuitive, multilingual 3.5’’ HMI.

- Full machine and synergy updates via USB stick.

- Job memory for up to 200 welding programs for recurring tasks.

- Portability function: user JOBS and machine configuration can be loaded/saved/transported via USB stick.

- Traceability of all weld beads in accordance with EN 3834.

- Calibration mode for welding accessories to adjust the voltage displayed.

- User mode for sharing the product with several users.

- Free online tool for customizing the interface.

ERGONOMIC

- Reinforced wheels for stability manoeuvrability

- Gas cylinder support for up to 4 m3 (20 L)

- IP23S rated to cope with demanding environments

- Storage compartment

- Easy polarity change on front panel

- LED lighting on wire feeder and spool

- Viewing window to check filler wire consumption

Download Catalogue