Welding machines are crucial tools in various industries, ensuring the integrity and strength of welded joints. To maintain their efficiency and accuracy, two important processes are carried out is calibration and validation. While often used interchangeably, these terms represent difference procedures in ensuring the reliability and precision of welding machines.

Calibration:

Calibration involves adjusting and verifying the accuracy of welding machine settings and parameters against a known standard. It ensures that the machine performs consistently and accurately.

- Process: During calibration, precise measurements and adjustments are made to align the machine’s output with established standards. This may include adjusting voltage, current, wire feed speed, gas flow rate, etc.

- Purpose: Calibration ensures that the welding machine operates within specified tolerances, minimizing deviations and errors in the welding process.

- Frequency: Calibration is typically performed regularly, according to manufacturer recommendations or industry standards, to maintain the machine’s accuracy over time.

Validation:

Validation assesses the overall performance and capability of the welding machine to consistently produce welds that meet predetermined quality criteria.

Process: Validation involves testing the welding machine under various operating conditions and evaluating its ability to produce welds that meet

- specified quality standards. This may include testing weld bead appearance, penetration depth, strength of the welding machines.

- Purpose: Validation ensures that the welding machine is capable of consistently producing welds of acceptable quality, meeting the requirements of relevant codes, standards, or customer specifications and provide certificates.

- Frequency: Validation is typically conducted initially upon installation or after significant modifications to the machine. Periodic revalidation may also be necessary to ensure continued compliance with quality standards of the welding machines.

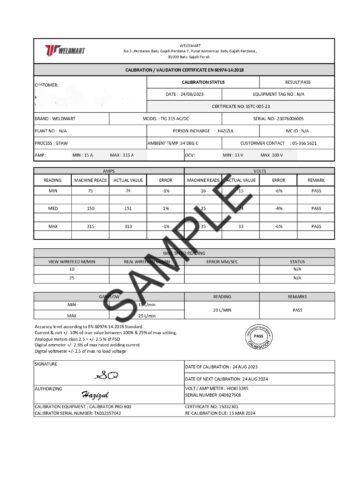

Calibration and Validation are both essential for maintaining the reliability and performance of welding machines, they serve distinct purposes. Calibration focuses on adjusting and verifying machine settings to ensure accuracy, while validation evaluates the machine’s capability to consistently produce quality welds. Both processes are essential for maintaining quality standards and achieving reliable welds. At WELDMART we are committed to providing superior calibration and validation services and certificate to meet the evolving needs of the welding industry.

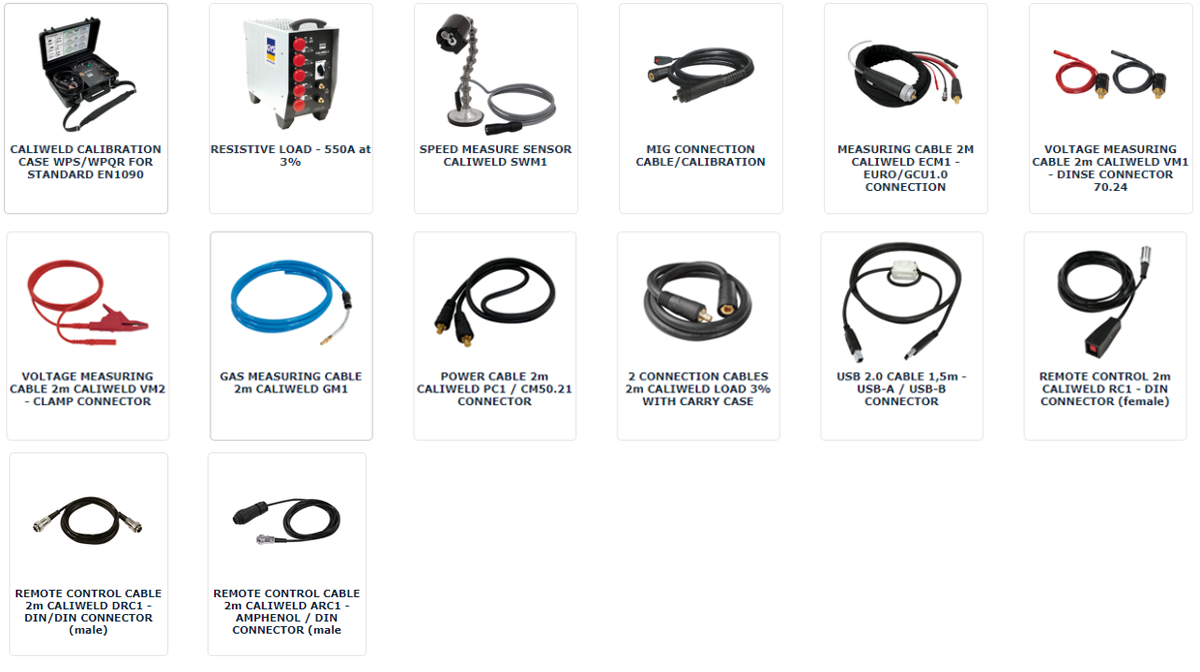

WELDMART offers comprehensive validation services to ensure that welding machines deliver optimal performance in diverse operating environments. Our experienced engineers conduct a testing and analysis to validate the functionality and reliability of each machine, thereby providing our clients with confidence in their welding processes and We are also using validation machine from GYS France plays a crucial role in ensuring the quality and reliability of welding equipment and tools produced by the company. By subjecting products to rigorous testing and validation procedures, it helps maintain high standards of excellence and customer satisfaction. These are the welding GYS Caliweld Accessories tools.

Moreover , Proweld Training Centre Sdn Bhd also provide the maintenance training program which is comprehensive instruction and hands-on experience in maintaining welding equipment and tools.

Moreover , Proweld Training Centre Sdn Bhd also provide the maintenance training program which is comprehensive instruction and hands-on experience in maintaining welding equipment and tools.

Theory Sessions: Participants are introduced to the theoretical aspects of welding equipment maintenance. This includes topics such as understanding different types of welding machines, identifying common issues and troubleshooting techniques, interpreting technical manuals and diagrams, and grasping safety protocols related to maintenance activities.

Practical Training: A significant portion of the program involves hands-on practical training. Participants get the opportunity to work directly with welding equipment and tools under the guidance of skilled instructors. They learn how to conduct routine maintenance tasks, perform inspections, diagnose problems, and execute repairs or adjustments as needed.

Certification Opportunities: Upon completion of the maintenance training program, participants may have the opportunity to obtain certifications or endorsements that validate their competency in welding equipment maintenance. These certifications can enhance their credibility and marketability in the industry.

Maintenance training program offered by Proweld Training Centre equips participants with the knowledge, skills, and confidence to effectively maintain welding equipment and tools, contributing to improved equipment reliability, safety, and productivity in industrial setting.

For more information about our calibration and validation process

WELDMART

NO, 3A Persiaran Batu Gajah Perdana 7,

Pusat Komersial Batu Gajah Perdana,

31000 Batu Gajah Perak

No Tel: 05-3665621 / Email: info@weldmart.com.my Weldmart Website: www.weldmart.com.my

Please visit the youtube channel to get more information about Caliwed