A Welding Procedure Specification (WPS) is the formal written document describing welding procedures, which provides direction to the welder or welding operators for making sound and quality production welds as per the code requirements.

A Welding Procedure Specification (WPS) is the formal written document describing welding procedures, which provides direction to the welder or welding operators for making sound and quality production welds as per the code requirements.

The purpose of the document is to guide welders to the accepted procedures so that repeatable and trusted welding techniques are used.

A WPS is developed for each material alloy and for each welding type used. Specific codes and/or engineering societies are often the driving force behind the development of a company’s WPS.

A WPS is supported by a Procedure Qualification Record (PQR or WPQR). A PQR is a record of a test weld performed and tested (more rigorously) to ensure that the procedure will produce a good weld.

It is the responsibility of every individual organization to conduct the welding procedures and welder qualifications tests and record and follow up the code like boiler pressure vessel code ASME section IX.

The scope of our project is to understand the requirements of the pressure vessel code with regards to the maintenance of quality of welding and how it is ensured.

We will prepare a welding procedure as per the boiler pressure vessel code, witness the welding for monitoring the welding variables like current, voltage, type of electrode, type of material etc.

Witnessing the mechanical tests like Tensile Test, Bend Test of the test specimens which are prepared as per the standard.

I. INTRODUCTION

[1] Welding Procedure Specification (WPS). A WPS is a written qualified welding procedure prepared to provide direction for making production welds to Code requirements. The WPS or other documents may be used to provide direction to the welder or welding operator to assure compliance with the Code requirements.

A WPS used for Code production welding shall be available for reference and review by the Authorized Inspector (AI) at the fabrication site. A WPS is supported by a Procedure Qualification Record (PQR).

Procedure Qualification Record (PQR). The PQR is a record of variables recorded during the welding of the test coupons. It also contains the test results of the tested specimens. Recorded variables normally fall within a small range of the actual variables that will be used in production welding.

[2] WPS is a set of welding instructions. It aids in planning and ensuring quality control of the welded product as well as future reproductions of the product.

Welding parameters, such as joint design, position, base metals, electrical characteristics, filler metals, technique, shielding, preheat, and post-weld heat treatment are all detailed in the WPS document.

WPS further explains the rules and details of the test and how the pieces should be assembled. Simply put, a WPS is like a blueprint for welders to produce the same quality of welded product over and over again.

Product Qualification Record is another type of document that also refers to welding. However, unlike WPS, the PQR document’s purpose is to serve as a checklist or record of compliance regarding the standard requirements of an appropriate welding procedure.

The PQR form covers all the welding parameters in the WPS document. In addition, it also includes some observations or other matters regarding welding procedures and specific tests like tensile tests and guided bend tests. It may also show the visual inspection and fillet weld test results.

Another important component of the PQR is the disclosure of relevant information, such as the welder’s name and the name of the person who did the inspection, and even the dates with the acknowledgement of the manufacturer or contractor.

The PQR is prepared by a qualified or licensed individual and submitted to the people concerned . The inspector will then endorse the company and its product to the industry and market.

A PQR is seen as complementary to a WPS because there are times when the PQR document is used to make a WPS document.

A. Stages in Welding Procedure and Welder Approval

B. American Society of Mechanical Engineers [ASME]

In 1911, The American Society of Mechanical Engineers established the Boiler and Pressure Vessel Committee to formulate standard rules for the construction of steam boilers and other pressure vessels. In 2009, the Boiler and Pressure Vessel Committee was superseded by the following committees:

-

- Committee on Power Boilers (I)

-

- Committee on Materials (II)

-

- Committee on Construction of Nuclear Facility Components (III)

-

- Committee on Heating Boilers (IV)

-

- Committee on Nondestructive Examination (V)

-

- Committee on Pressure Vessels (VIII)

-

- Committee on Welding, Brazing, and Fusing (IX)

-

- Committee on Fiber-Reinforced Plastic Pressure Vessels (X)

-

- Committee on Nuclear Inservice Inspection (XI)

-

- Committee on Transport Tanks (XII)

-

- Technical Oversight Management Committee (TOMC)

-

- Committee on Power Boilers (I)

Section IX of the ASME Boiler and Pressure Vessel Code relates to the qualification of welders, welding operators, brazers, and brazing operators, and the procedures that they employ in welding and brazing. It is divided into two parts: Part QW gives requirements for welding and Part QB contains requirements for brazing.

ASME Section IX is a document referenced for the qualification of material joining processes by various construction codes such as Section I, III, IV, VIII, XII, etc. These particular construction codes apply to specific types of fabrication and may impose additional requirements or exemptions to Section IX qualifications.

Qualification in accordance with Section IX is not a guarantee that procedures and performance qualifications will be acceptable to a particular construction code.

C. Process Parameters Involved in WPS

1) Welding process

Welding is a process of joining two similar or dissimilar materials by the application of heat and filler metal with or without application of pressure. On cooling, the molten edges fuse together to form a strong joint. A filler metal is added to the molten parent metal.

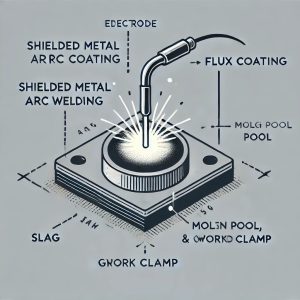

The most popular processes are shielded metal arc welding (SMAW), gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW). All of these methods employ an electric power supply to create an arc which melts the base metal(s) to form a molten pool.

The filler wire is then either added automatically (GMAW) or manually (SMAW & GTAW) and the molten pool is allowed to cool. Shielded metal arc welding (SMAW) is an arc welding process in which the coalescence of metals is produced by heat from an electric arc that is maintained between the tip of a covered electrode and surface of the base metal in the joint being welded.

In this welding procedure specification (WPS) the shielded metal arc welding(SMAW) process is used as per boiler vessel pressure code ASME Sec Ix.

In this process the heat required for welding is generated by the electric arc formed between metallic electrode and base metal. When the welder touches the plate to be welded with the electrode, it directly short circuits the power supply and immediately a heavy current flows which melts the tip of the electrode like blowing of the fuse, thus initiating the welding arc.

If the welder maintains the arc gap, the arc continous to remain stable and the arc heat melts the plate, electrode and the flux coating.

2) Base Metal

The base metal used is mild steel and its specification type and grade as per ASME Sec IX is IS2062 Grade B.

[3] The IS2062 Gr B mild steel is general structural steel for fabrication. The chemical composition of IS2062 Gr B is

| Grade | C % Max | Mn % Max | S % Max | P % Max | Si % Max | C.E % Max |

| B | 0.22 | 1.5 | 0.045 | 0.045 | 0.04 | 0.041 |

Table 1: chemical composition of IS2062 Gr B

Mechanical properties IS2062 E250 Grade B

| Grade | UTS (MPa) Min | Y.S (MPa) Min | E I % Min |

| B | 410 | 250 | 23 |

Table 2: mechanical properties of base metal IS2062 Mild steel UTS – Ultimate tensile stress, YS- Yield strength, E I- Elongation in percentage.

3) Filler Metal

Electrode and filler wires are used as filler metals which fills or joints the base metals in any welding process. For different base metals different types of filler metals and electrodes should be used.

They should be as recommended by the welding engineering department. They are available in different sizes for different weld edges. The filler metal used for shielded metal arc welding process is E7018.

4) Welding Position

The weld position is considered to be an important factor. In this WPS (welding procedure specification) the weld progression is uphill and welding position is 3G.

5) Preheat

Preheat is always specified as the minimum temperature to which the parent material must be heated before welding and maintained during welding. The purpose of preheat is to minimize the risk of cracking in the weld metal and heat-affected zone. uniform preheating reduces the distortion to welding.

6) Post Weld Heat Treatment

Post weld heat treatment (PWHT) defined as any heat treatment after welding, is often used to improve the properties of a weldment. In concept, PWHT can encompass many different potential treatments; however, in steel fabrication, the two most common procedures used are Post heating and Stress relieving.

PWHT is required to increase the resistance to brittle fracture and relaxing residual stresses. Other desired results from PWHT may include hardness reduction, and material strength enhancements. As per boiler vessel pressure code the PWHT is carried for plates thickness above 40mm.

II. EXPERIMENTAL PLAN AND DETAILS

A. Experimental Setup and Work Materials

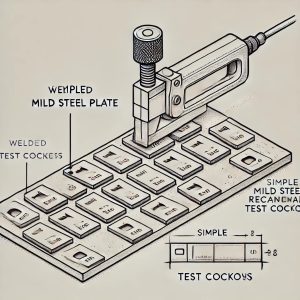

The experiments were conducted at shivpra cranes, Hyderabad on mild steel IS2062 Gr. B Plate of thickness 16mm were cut into 20x150x300 and welded with same dimension plate.

B. Preparation of Test Coupon

The welded specimen is cut and machined into number of test coupons. the purpose of making test coupons is to conduct tensile test and bend test for qualifying the codes as per ASME Sec ix.

[4] The test coupons are prepared as per boiler vessel pressure code i.e ASME Sec ix. The number of test coupon prepared for tensile test is two, and four test coupons are prepared for bend test. The test coupon is shown in the figure below.

C. Electrical Characteristics

| Weld passes | Root pass | Filler pass | Capping | |

| Process | Smaw | Smaw | Smaw | |

| Filler | classification | E7018 | E7018 | E7018 |

| metal | Dia | 3.15mm | 4mm | 4mm |

| Current type & polarity | DCEP | DCEP | DCEP | |

| Amps(range) | 100-120 | 140- 180 | 140-180 | |

| Volts(range) | 22-26 | 24-28 | 24-28 |

Table 3: electrical characteristics

The electrical characterstics defines the theoretical wps values prepared by the organization head. This electrical characterstics will followed by weld operator during welding. Its is also inspected by weld inspector during welding.

D. Testing Of Weld Specimen

[5] The design of nearly every component and structure is based on minimum tensile properties. As welded joints contain metallurgical and often compositional differences that result from the welding process, the effects of these changes on the mechanical properties of the weldment must be assessed.

Some strength tests, such as tension tests, measure tensile strength directly, while others, such as the peel test, verify that the weld is as strong as the base metal. The techniques used to evaluate the strength of weldments are discussed below.

1) Mechanical Testing

Mechanical testing of weld joints may be carried for following reasons

– Welding procedure approval

– Welder approval

– Production quality approval

In mechanical testing representative test samples are produced under similar conditions to the in service components are normally used and comparison is made.the purpose of mechanical testing is to asses the properties of weld joints.

The most frequently used mechanical tests are

1) Tensile test

2) Bend test

3) Hardness

4) Impact

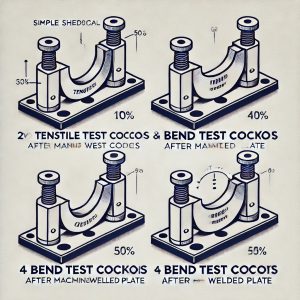

1) Tensile test: in tensile test stress is applied on opposite direction to pull the two ends apart. The tensile test used asses the following:

– Yield point of the specimen

– Ultimate tensile strength

– Ductility of the specimen, expressed as % elongation.

2) Bend test: the bend test is usually carried out to determine the soundness of the weld zone. The commonly applied bend test is transverse bend test, there are three ways to perform this type of bend test.

– Face bend test

– Root bend test

– Side bend test

[6] Transverse bend tests may be either face, root, or side tests, depending upon the area that is in tension during test.

Face bend tests are performed with weld face in tension. Root bend tests are performed with weld root in tension, and side bend can be bent toward either side. Side bends typically can be used when bend testing plates are thicker than 10mm to 19mm.

The side bend tests strain entire cross section of the weld. Thus they are especially useful for exposing the discontinuities that may not contribute to failure in face or root bend tests because of their location near the mid thickness. The figure below shows the three types of bend test.

E. Format for WPS

The written document of Welding Procedure Specification will be in order mentioned as below which will be followed by the Welder.

QW-482 WELDING PROCEDURE SPECIFICATIONS (As per ASME Sec IX)

| Joint (QW-402) | |

| Joint Design | All |

| Root Spacing | 2mm – 3mm |

| Backing | Yes |

| Backing Material | Weld Metal |

Table 4: Joint Design

| Base Metals (QW-403) | ||||||||

| P. No | 1 | Group No | 1 | To | P. No | 1 | Group No | 1 |

| Specification type and grade | IS2062 Gr B | To | Specification type and grade | IS2062 Gr B |

| Thickness Range | ||||

| Base Metal | Groove | 5mm- 32mm | Fillet | All |

| Pipe Dia Range | Groove | All | Fillet | All |

| Min. Pass thickness<=1/2in. (13mm). [Yes/No] | YES | |||

| Filler Metals (QW-404) | ||||

| Process | SMAW | |||

| Spec. No [SFA] | 5.1 | |||

| AWS No. [Class] | E 7018 | |||

| F. No | 4 | |||

| A. No | 1 | |||

| Size of filler metals | 3.15, 4mm | |||

| Supplemental filler metals | NA | |||

| Weld metal thickness range | Groove: 5mm-32mm | |||

| Fillet: All Sizes | ||||

| Trade name [Flux] | NA | |||

| Electrode Flux [Class] | NA | |||

| Type of Flux | NA | |||

| Consumable Inert | NA |

III. RESULTS AND DISCUSSIONS

In this paper the importance of wps is studied and applied to shielded metal arc welding with reference to ASME Sec IX boiler pressure vessel code. The welding procedure will be approved by inspection services.

The mechanical tests like tensile test, guided bend test are part of wps which are obtained better results with IS2062 E250 Grade B as base metal which is used as structural steel for fabrication.

Mechanical Test Report

| SL No | Identification | Specification/grade | Dimensions of Specimen, mm | Lo mm |

| 01 | Tensile coupon T1 | IS:2062-2011 E250 GR B | 15.9×18.9 | 50 |

| 02 | Tensile coupon T2 | IS:2062-2011 E250 GR B | 15.9×18.8 | 50 |

| Sl No | 01 | 02 |

| L0 (mm) | 50 | 50 |

| A0 (mm2) | 300.5 | 298.5 |

| Yield Load (KN) | 98 | 98 |

| Ultimate Load (KN) | 141.90 | 141.64 |

| Lf (mm) | 66.3 | 65.03 |

| Yield Strength (N/mm2) | 328.26 | 326.11 |

| UTS (N/mm2) | 472.19 | 474.43 |

| Elongation (%) | 32.7 | 30.06 |

Lo= gauge length, Ao= initial area of test coupon Lf= final gauge length, Ao= final area

The tensile test results is said to be passed when the test specimen achieves minimum Ultimate tensile stress, yield stress and elongation.

The minimum ultimate tensile stress, yield strength, and elongation as per boiler pressure vessel code is 410MPa(UTS), 250MPa(Y.S), 23%(Elongation). The obtained results of tensile test coupons are 472.19MPa(UTS), 474.43MPa(UTS), and corresponding elongation results are 32.7%, 30.06%.

The type of bend test conducted was side bend test, the side bend test is said to be passed when there is no discontinuities such as cracks, voids etc is not found in the weld zone. Hence all four side bend test are passed there is no defects or discontinuities are found as shown in figure below.

IV. CONCLUSIONS

In this paper a recent study on welding procedure specifications has been made which represents the following facts:

1) The boiler pressure vessel code i.e ASME Sec IX is followed and prepared a WPS with shielded metal arc welding process and achieved better results. From this wps the welder is going to follow up certain weld parameters during SMAW in order to minimize rework at fabrication sites.

2) From this WPS the welder performance can be established in the fabrication industry i.e welder performance qualifications, in which the welder performance is supposed to be enhanced by considering mechanical tests conducted on welded test coupon made by welder with certain welding position, electrode, base metal etc.

3) Preparation of wps improves welding procedure, performance of individual when there is a repitative work comes at fabrication site such that the welder is selected based on performance.

4) By following wps the fabrication industry will benefit better production quality without wastage and rework of material.

5) From the wps the better quality welders with different welding process and different welding positions will be obtained in the fabrication industry.

REFERENCES

[1] American Society of mechanical engineers section IX boiler pressure vessel code committee on welding,brazing,and fusing. W.J. Sperko, M. Bernasek,

J.G. Feldstein, P.D.Flenner, J.S. Lee, R.M. Jessee, M.J.Rice, T.Melfi, D.K. Peetz.

[2] American society of mechanical engineers boiler pressure vessel code section IX sub committee on general requirements, P.L. Sturgill, E.W. Beckman , J.P.Bell, G. Chandler, P.R. Evans, A. Howard, R.M.Jessee.

[3] American society of mechanical engineers, boiler pressure vessel code section IX, sub committee on materials, M.Bernasek, T.Anderson, J.L.Arnold, E.Cutlip, L. Harbison, P.L Sturgill, S.S.Fiore.

[4] American society of mechanical engineers, boiler pressure vessel section ix, sub committee on procedure qualification, D.A.Bowers, M.J.Rice, W.J.Sperko, T.C.Wiesner, S.A Spargue, M.B.Sims.

[5] American Welding Society (AWS) Committee on Mechanical Testing of Welds, 1998, Standard Methods for Mechanical Testing of Welds, ANSI/AWS

[6] American Society for Testing and Materials Subcommittee E28.02. 1997. Standard test method for guided bend test for ductility of welds. ASTM E 190-92 (1997).