Have you ever wondered what makes machines in factories work so smoothly, day in and day out? Or how elevators know exactly when to open, close, and stop at the right floor? Behind the scenes, there’s a quiet hero making it all happen — the PLC, or Programmable Logic Controller.

Let’s take a closer look at what PLC programming is, where it’s used, and why it’s such an important part of the modern world.

What Is a PLC?

A PLC is a small industrial computer that controls machines, processes, or systems. It receives input signals (like buttons being pressed or sensors being triggered), makes decisions based on a set of instructions (a program), and sends output signals to control devices like motors, lights, or alarms.

Think of it like the brain of a factory machine.

Instead of manually operating everything, we can program the PLC to do exactly what we want — and it will repeat the process perfectly, over and over.

Where Can You Find PLCs?

PLCs are everywhere, often hidden in plain sight:

- Traffic lights — to manage light cycles based on time or vehicle detection

- Factory machines — to assemble cars, fill bottles, or pack boxes

- Elevators — to respond to button presses and floor selection

- Water treatment plants — to control valves and pumps automatically

- Theme park rides — to keep riders safe with perfect timing and coordination

Basically, if it moves, counts, turns on/off, or follows a sequence — a PLC might be involved.

What Is PLC Programming?

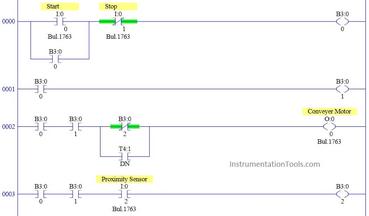

PLC programming is the process of creating a set of instructions that tell the PLC how to respond to various inputs and what actions to take. Most PLCs use a visual language called Ladder Logic, which looks like a digital version of electrical diagrams.

Programs can be simple — like turning on a light when a switch is pressed — or complex, involving multiple steps, timers, and conditions.

Because PLCs are used in mission-critical environments, the programs need to be reliable, fast, and easy to troubleshoot.

Why Is PLC Programming Important?

PLC programming is a big deal because it:

- Improves efficiency — Automates repetitive tasks without errors

- Boosts safety — Controls emergency systems and prevents accidents

- Reduces cost — Cuts down on human labor and energy waste

- Enables precision — Ensures processes are timed perfectly

It’s the backbone of industrial automation — a growing field that’s changing how everything is made and moved.

Who Can Learn PLC Programming?

You don’t have to be a genius or an engineer to start learning PLC programming. Many students, technicians, and even hobbyists pick it up through:

- Online courses and YouTube tutorials

- Simulation software that lets you test your code

- Hands-on kits with small PLC units

As more industries adopt automation, PLC skills are in high demand, with careers in manufacturing, robotics, smart factories, and more.

Proweld Training Centre provides specialized training in PLC and automation to meet this growing demand. Their offerings include:

- PLC Fundamentals 1 — an introduction to basic PLC concepts and operations

- Delta HMI Programming Training — focused on designing human-machine interface applications using DOPSoft software

- FluidSIM Pneumatic Training — covering simulation and understanding of pneumatic systems using FluidSIM software

- Electropneumatic Control System–set up a wide variety of basic industrial automation control circuits using ladder diagrams and Boolean Logic.

These programs equip learners with practical, job-ready skills in industrial automation. For more information, visit Weldmart Website.

What’s Next for PLCs?

PLCs are evolving. Many now support remote access, IoT integration, and cloud connectivity. That means you can program or monitor a machine from a smartphone — or collect data from hundreds of machines to improve performance.

As industries move toward smart factories, PLC programmers will be at the center of it all.

Final Thoughts

From helping package your snacks to running complex assembly lines, PLC programming quietly powers our modern world. It’s a mix of logic, creativity, and problem-solving — and it’s more accessible than ever.

If you enjoy technology and want to be part of the automation revolution, PLC programming might just be the spark that lights your career.

Email: infopwtc@gmail.com

Office number: 05-3665621

PIC: En Badrul Hisyam Bin Ahmad

Contact number: 014-908 7102

Address: No 3 & 3A, Persiaran Batu Gajah Perdana7, Pusat Komersial Batu Gajah Perdana, 31550Pusing, Perak.