Are you ready to experience the next generation of welding training? Look no further than the Soldamatic Welding Simulator 2023! Designed to meet the evolving needs of the welding industry, this cutting-edge simulator brings a new level of realism, interactivity, and convenience to welding education. Get ready to step into a virtual world where welding becomes a tangible reality. The Soldamatic Welding Simulator 2023 offers an incredibly lifelike welding experience that mirrors real-world scenarios. With high-definition graphics, accurate physics, and realistic welding effects, you’ll feel as though you’re in an actual welding workshop.

8 Steps On Why Augmented Reality training is the best solution for TVET program?

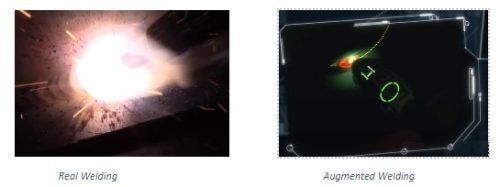

Realistic Simulations: Augmented training provides realistic, immersive simulations that closely replicate real-world scenarios. This realism enhances the learning experience, allowing trainees to engage in lifelike situations without the risks associated with actual environments.

1. Safety and Risk Mitigation:

In industries like welding, where safety is paramount, augmented training offers a safe environment for trainees to practice without the potential dangers of live welding. It reduces risks to both the trainees and expensive equipment.

Traditional welding training is based on trial and error and with the simulator we can create the guides that are impossible in real welding to let the students know when they are doing the errors in real time .

2. Instant Feedback and Analysis :

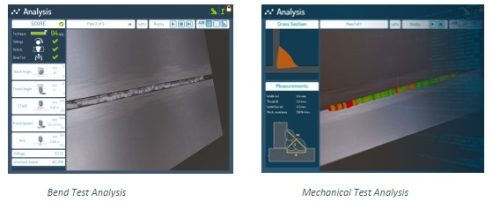

Augmented training often includes instant feedback mechanisms that analyse trainee performance in real-time. This immediate feedback loop helps learners understand their strengths and weaknesses, allowing them to make necessary adjustments promptly. The software technology allows the TRAINNER to provide a wide range of training modules, meticulously crafted to provide a comprehensive learning experience. Whether you’re a beginner or an experienced welder looking to refine your skills, the Soldamatic Welding Simulator 2023 offers tailored exercises that cover various welding techniques, positions, and materials. From basic arc welding to advanced pipe welding, you’ll have the opportunity to practice and perfect your skills in a risk-free environment.

3. Cost Effciency and Accessibility

Traditional training methods can be costly due to material expenses, equipment, and space requirements. Augmented training eliminates many of these costs, making it a more cost-effective option. Additionally, it’s often accessible remotely, enabling learning from anywhere with an internet connection. Gone are the days of relying solely on traditional welding workshops for training. The Soldamatic Welding Simulator 2023 brings unparalleled convenience and cost-efficiency to the table. Now, you can practice your welding skills anytime, anywhere, without the need for expensive equipment or materials. This simulator is accessible through various platforms, including desktop computers, laptops, and VR headsets, ensuring that you have the flexibility to train according to your schedule. On average, a welding training facility will be able to save at least 50% of its materials and operational costs.

4. Immediate Feedback and Performance Analysis

Forget about waiting for an instructor to assess your work. With the Welding Simulator, you’ll receive instant feedback on your technique, accuracy, and overall performance. The simulator’s advanced algorithms analyses your welds in real-time, providing detailed insights and suggestions for improvement. This instant feedback loop enhances your learning process, allowing you to make adjustments and progress rapidly.

5. Customization and Adaptability

Augmented training solutions are highly adaptable and customizable. They can be tailored to fit the needs of various learners, offering different difficulty levels, scenarios, or skill-specific modules. This versatility allows for a personalized learning experience.

6. Technological Advancement

Augmented training leverages cutting-edge technologies like virtual reality (VR), augmented reality (AR), and artificial intelligence (AI) to create engaging and effective learning experiences. These technologies continuously evolve, ensuring that training methods stay updated and aligned with industry standards. The technology also provides the students real content and practices to learn, or they can use their own “Welding Procedure Specification(WPS).

7. Retention and Engagement

The immersive nature of augmented training often leads to higher engagement levels among trainees. The interactive and dynamic nature of these training methods promotes better retention of information and skills.

8. Environmental Impact

By reducing the need for physical resources, augmented training minimizes the environmental impact associated with traditional training methods. It promotes sustainability by decreasing material wastage and energy consumption.

In summary, augmented training is the best solution because it provides a safe, cost-effective, adaptable, and engaging learning environment that closely simulates real-world scenarios. Its incorporation of cutting-edge technology ensures that training methods remain at the forefront of innovation, preparing individuals effectively for the demands of their respective industries.