As global industries continue to evolve, there is a growing demand for highly skilled workers in technical and vocational fields. Weldmart Technology Sdn Bhd is proud to support Technical and Vocational Education and Training (TVET) programs with our latest innovation, the REDSPRAY PAINTING SIMULATOR RED-PS200. This advanced virtual reality (VR) system is designed to help future painters, powder coaters, and blasters gain the hands-on experience they need, all while eliminating the drawbacks of traditional training methods.

How Industrial and TVET Programs Benefit from using Simulator as a training aid?

- TVET programs are focused on equipping students with practical skills that meet industry standards. With the SIMULATOR, educational institutions, training centres, and apprenticeship programs can provide students with a high-quality learning experience that mimics real-world scenarios.

Who Can Use It?

The SIMULATOR s ideal for various groups within the TVET sector:

Vocational Schools and Colleges: Students enrolled in painting, coating, and surface preparation courses can use the simulator as part of their curriculum, ensuring they graduate with a high level of competence.

- Technical Training Institutes: Trainees in programs that focus on automotive, aerospace, shipbuilding, and industrial manufacturing can use the simulator to hone their spray painting and coating skills before transitioning to real-world applications.

- Apprenticeship Programs: Employers can integrate the simulator into their apprentice training programs, reducing material costs while ensuring apprentices master proper techniques early in their careers.

- Industrial Training Facilities: Skill employees can use the simulation as a true-to-life learning environment that mirrors real-life work and scenarios. The simulation can put real work knowledge and skills into practice within a safe environment.

- University Research & Development programs: Post graduate students will be able to create different scenarios or environments within a safe environment to test our their theories and ideas.

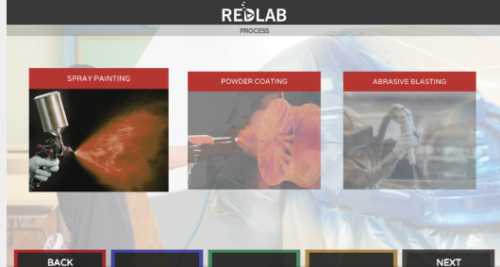

REDSPRAY PAINTING SIMULATOR RED-PS200, is designed to meet this need, offering an immersive, hands-on experience in multiple surfaces finishing techniques, including spray coating, powder coating, and abrasive blasting.

This powerful simulator is transforming Technical and Vocational Education and Training (TVET) programs by providing students with a safe, cost-effective, and environmentally friendly alternative to traditional training methods. Here’s how it’s reshaping the future of training in various coating technologies:

- Spray Coating

- Spray coating is widely used across various industries, from automotive to aerospace, where precise control over coating thickness and application uniformity is crucial. The REDSPRAY PAINTING SIMULATOR accurately replicates the process, allowing trainees to master the art of handling spray guns, controlling spray patterns, and ensuring proper coating thickness—all without wasting materials or exposing students to hazardous chemicals.

- Powder Coating

- Powder coating, known for its durability and environmentally friendly nature, has become the go-to choice for many industrial applications. Through the simulator, students learn the fundamentals of powder application, from charging the powder particles to ensuring an even and efficient application. Trainees can practice in a risk-free setting, gaining valuable skills that can be directly applied in the workforce.

- Abrasive Blasting

- In industries such as shipbuilding, automotive restoration, and metal fabrication, abrasive blasting is essential for surface preparation. The REDSPRAY PAINTING SIMULATOR enables students to perfect their techniques in abrasive blasting by simulating various blasting materials and surface conditions. This ensures that they are proficient in achieving the desired surface finish while minimizing the risk of accidents and material wastage in real-life scenarios.

Why Choose VR-Based Training?

The REDSPRAY PAINTING SIMULATOR RED-PS200 offers numerous advantages for TVET programs. Here’s why VR-based training is a game-changer:

- Hands-On Experience Without Material Waste: One of the main challenges in traditional training is the significant waste of paint, coating materials, and other consumables. With VR training, students gain practical experience without the need for physical materials, greatly reducing costs and waste.

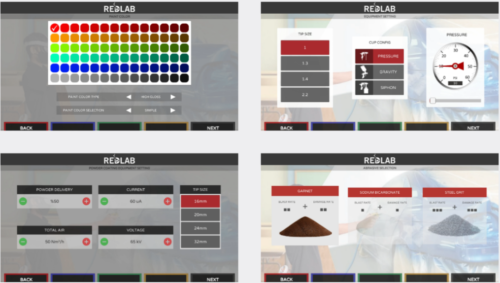

- Immediate Feedback and Improvement: In traditional training, mistakes can be costly and time-consuming to correct. The simulator analyses key metrics such as speed, angle, distance, and transfer efficiency while also identifying common painting errors such as drips, orange peel, and dry spray. This real-time feedback allows students to adjust their techniques immediately, accelerating their learning curve.

- Adaptable to Multiple Techniques: The REDSPRAY PAINTING SIMULATOR offers various painting and coating techniques, including Airless and air-assisted airless spraying, and powder coating. Students can practice with different cup configurations and gun types, ensuring they are ready for multiple industry applications, from automotive painting to industrial coatings.

- Safe and Controlled Learning Environment:The simulator provides a safe space for trainees to practice without the risks associated with handling hazardous materials. This not only protects students but also creates a controlled environment where they can practice complex techniques without fear of injury or accidents.

VR-based simulators like the REDSPRAY PAINTING SIMULATOR RED-PS200 play a critical role in preparing students for successful careers. By adopting this technology, TVET programs can ensure their graduates are well-prepared to meet the demands of industries such as automotive manufacturing, construction and more.

At Weldmart Technology Sdn Bhd, we believe in empowering the next generation of skilled workers. The REDSPRAY PAINTING SIMULATOR RED-PS200 is more than just a training tool it’s an investment in the future workforce, enabling students to master essential skills while minimizing costs, enhancing safety, and promoting sustainability. For more information, please contact us at 05-3665621(Weldmart Technology Sdn Bhd Office) or email to us at info@weldmart.com.my.